Aluminum Panel Formwork System

· Raw Material: Aluminum alloy 6061-T6

· Panel Thickness: 4mm

· Weight: Around 23kg/m2

· Reuse times: >300times(if maintain well, it can be used for thousands of times)

· Suitable Projects: High Rise Residential buildings, condominiums, townhouses, small villas, etc.

Aluminum Formwork VS Plywood Formwork

The comparison between Aluminum Panel Formwork System and Plywood System

| Comparison | Aluminum Panel Formwork System | Plywood System | ||

| Economic consideration | Size | Standard sizes could achieve any structure. Easily handled | The sizes are changeable and non-standard. Difficult in assembly and disassembly. | |

| Plastering | No need | Need | ||

| Uses | More than 300 times (85%of formwork is standard) |

2 or 5 times A lot of plywoods and nails are consumed. |

||

| Early-stripping | Yes (One set of formwork with two sets of shoring systems) | No (Three sets of plywood formworks with three sets of shoring systems) | ||

| Construction Quality | Good finishing and verticality. | Easily expanding | ||

| Labor | Sufficient, No need professional workers and the common workers could operate skillfully after short-term training | requires professional workers. The workers directly effect the construction quality. While these workers are greatly required, and the cost would be higher. | ||

| Load | 60KN/m² | 30KN/m² | ||

| Safety | Construction site | Clean and Neat | Messy | |

| Environmental | Recovery value | 100% recycle Scrap cost could be 20-30% of the product price. |

No recycle value | |

| Material Consuming | More uses, environmental and energy-saving | Few uses. A lot of plywoods would be consumed. | ||

| Construction waste | Rarely | A lot of scraped plywoods and nails | ||

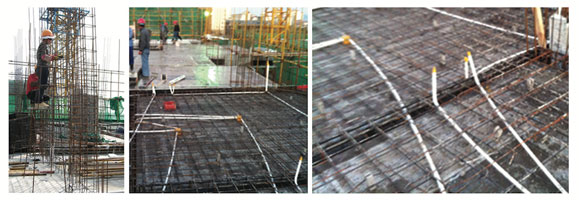

Construction Process

Step 1:

Level Survey

Step 2:

Reinforcement installation for wall & column formwork

Step 3:

Assembly of wall formwork & column formwork

Step 4:

Assembly of beam & slab formwork

Step 5:

Adjustment and Fixing of formwork

Step 6:

Reinforcement installation for beam & slab formwork

Step 7:

Concrete pouring and curing

Step 8:

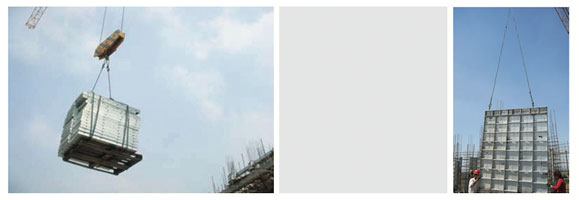

Dismantling of formwork

Step 9:

Form Transferring

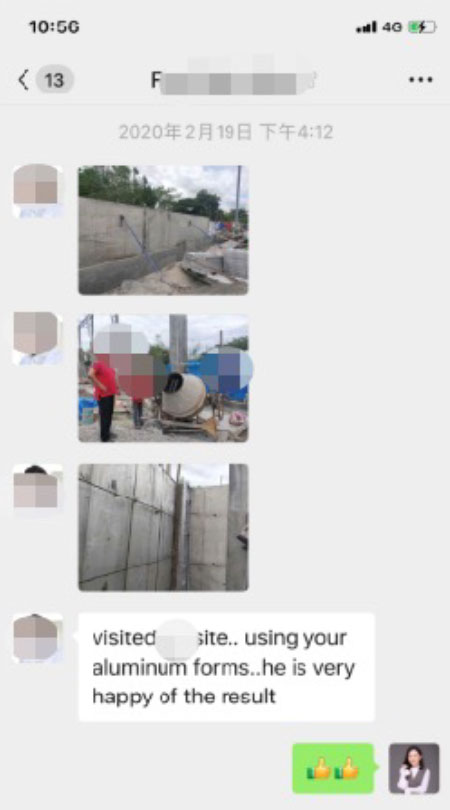

Comments

Get your solution

Customer satisfaction is our greatest recognition, and we will continue to provide you with high-quality aluminum formwork solutions.

Our Mission

Our aim is to supply our customers with safe, efficient, economical, environmental protecting, and energy-conserving products and manage to make construction much easier.